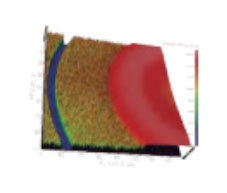

Can detect samples with steep angles

VT6000 series confocal microscope

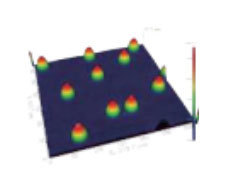

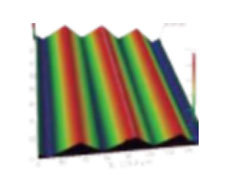

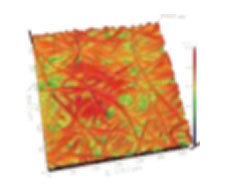

The VT6000 series confocal microscope is a detection instrument used for micrometer and nanometer level measurement of various precision components and material surfaces. Based on confocal technology, combined with a precision Z-axis scanning module and 3D modeling algorithm, it performs non-contact scanning of the component surface and establishes a 3D surface image. The system software processes and analyzes the 3D image of the component surface and obtains 2D and 3D parameters that reflect the surface quality of the component, thus achieving optical detection of the 3D measurement of the component surface morphology. It can measure various object surfaces, from smooth to rough, low reflectivity to high reflectivity, roughness, flatness, microscopic geometric profile, curvature, etc., of workpieces from nanometer to micrometer levels, providing more than 300 2D and 3D parameters based on four domestic and international standards, including ISO/ASME/EUR/GBT, as evaluation standards.

Keywords:

Microscope

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: VT6000 series confocal microscope

The VT6000 series confocal microscope is a detection instrument used for micrometer and nanometer level measurement of various precision components and material surfaces. Based on confocal technology, combined with a precision Z-axis scanning module and 3D modeling algorithm, it performs non-contact scanning of the component surface and establishes a 3D surface image. The system software processes and analyzes the 3D image of the component surface and obtains 2D and 3D parameters that reflect the surface quality of the component, thus achieving optical detection of the 3D measurement of the component surface morphology. It can measure various object surfaces, from smooth to rough, low reflectivity to high reflectivity, roughness, flatness, microscopic geometric profile, curvature, etc., of workpieces from nanometer to micrometer levels, providing more than 300 2D and 3D parameters based on four domestic and international standards, including ISO/ASME/EUR/GBT, as evaluation standards.

The VT6000 series confocal microscope is a detection instrument used for micrometer and nanometer-level measurement of the surfaces of various precision devices and materials. It uses confocal technology, combined with a precision Z-axis scanning module and 3D modeling algorithm, to perform non-contact scanning of the device surface and establish a surface 3D image. The system software processes and analyzes the 3D image of the device surface, obtains 2D and 3D parameters reflecting the surface quality of the device, and thus achieves optical detection of the 3D measurement of the device surface morphology. It can measure various object surfaces, ranging from smooth to rough, low reflectivity to high reflectivity, and roughness, flatness, micro-geometric profile, curvature, etc., of workpieces from the nanometer to micrometer level, providing more than 300 2D and 3D parameters based on four international standards: ISO/ASME/EUR/GBT, as evaluation standards.

Performance characteristics

1. High precision, high repeatability

1) Based on a rotating disk confocal optical system, combined with a high-stability structural design and excellent 3D reconstruction algorithm, it constitutes the measurement system, ensuring high measurement accuracy of the instrument.

2) The unique shock isolation design can reduce bottom vibration noise. The instrument is stable and reliable in most environments and has good measurement repeatability.2. Integrated measurement and analysis software

1) Measurement and analysis are operated on the same interface without switching. Measurement data is automatically statistically analyzed, realizing the function of fast batch measurement.

2) Visual window allows users to observe the scanning process in real time.

3) Combined with the automated measurement function of a custom analysis template, it can automatically complete the measurement and analysis process of multiple areas.

4) Five functional modules are complete: geometric analysis, roughness analysis, structural analysis, frequency analysis, and functional analysis.

5) One-click analysis, multi-file analysis. Freely combine analysis items, save them as analysis templates, perform one-click analysis of batch samples, and provide data analysis and statistical charts.

6) Can measure more than 300 2D and 3D parameters based on standards such as ISO/ASME/EUR/GBT.3. Precision control handle

Integrated X, Y, and Z directional displacement adjustment functions for quick completion of pre-measurement tasks such as stage translation and Z-axis focusing.4. Double anti-collision protection measures

In addition to software ZSTOP setting Z-axis displacement lower limit for anti-collision protection, a mechanical electronic sensor is also designed on the Z-axis. When the lens touches the sample surface, the instrument automatically enters an emergency stop state, maximizing instrument protection and reducing the risk of human operation.

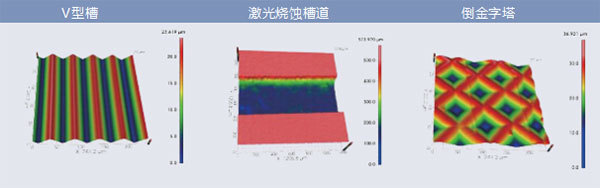

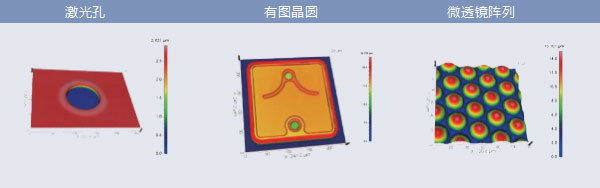

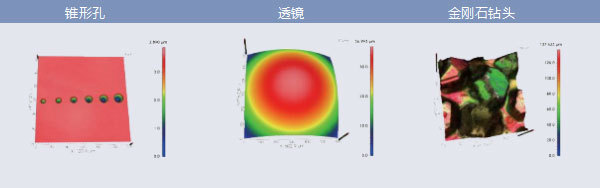

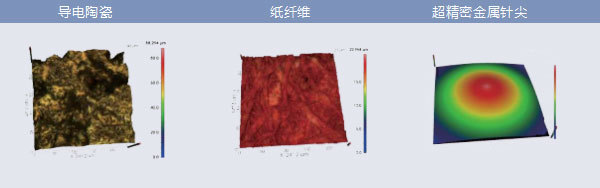

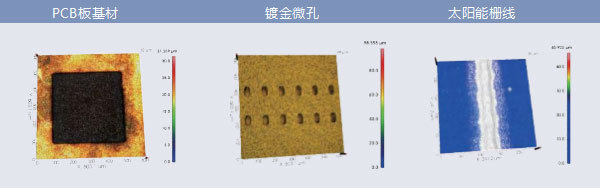

Application areas

Technical indicators

Instrument model VT6100 VT6200 VT6300 Travel range X 100mm 230mm 300mm Y 100mm 230mm 300mm Z 100mm 100mm 100mm External dimensions 520×380×600mm 720×580×1500mm 1000×900×1500mm Instrument weight 50kg 400kg 500kg Measurement principle Confocal optical system Microscope objective 10×, 20×, 50×, 100× Field of view 120×120 μm~1.2×1.2 mm Height measurement Repeatability*1 (1σ) 12nm Accuracy*1 ± (0.2+L/100) μm Display resolution 0.5nm Width measurement Repeatability*2 (1σ) 40nm Accuracy*2 ± 2% Display resolution 1nm XY displacement platform Load 10kg Control method Electric Z0-axis scanning range 10 mm Objective turret 5-hole electric Light source White LED Working environment

Power supply 100-240V AC, 50/60Hz, 2A Power 300W Operating temperature Temperature 15℃~30℃, temperature gradient < 2℃/60 minutes Relative humidity 5%~95%RH, no condensation Environmental vibration VC-C or better Other No strong magnetic field, no corrosive gases *1 Using a 50X objective lens to measure a 4.7µm standard step block in a laboratory environment

*2 Using a 50X objective lens to measure a standard engraved line sample in a laboratory environment

Previous Page

Related Products

Product Inquiry