● 100% surface roughness detection

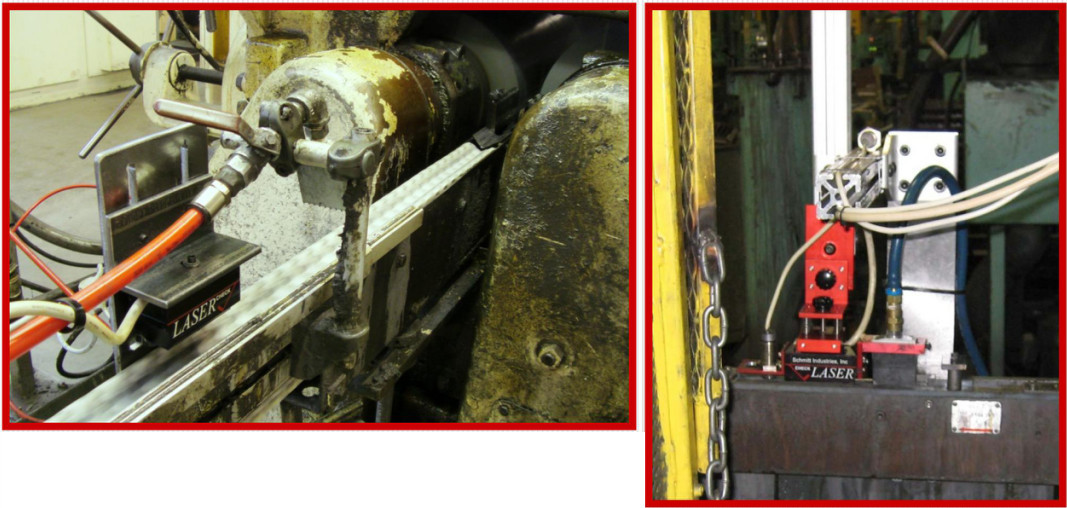

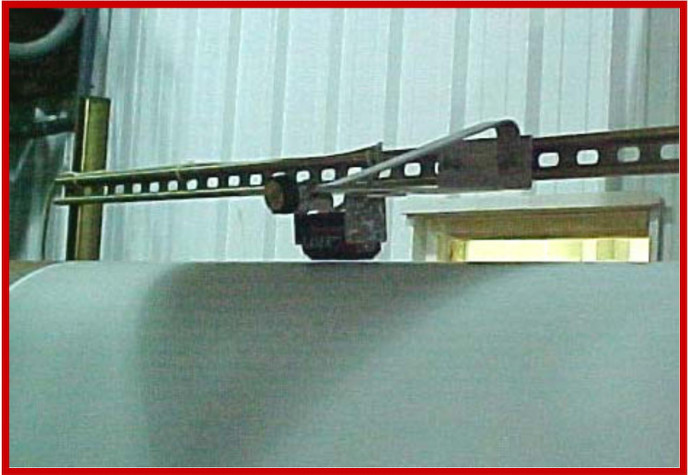

● Integrable into production lines

The Lasercheck non-contact surface roughness meter allows for on-site control of product surface roughness and is widely used in industries such as sheet materials, automotive parts, aerospace, electronics, solar energy, and printing. It enables fast, non-contact measurement without damaging the workpiece surface.

Keywords:

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

0

隐藏域元素占位

The Lasercheck non-contact surface roughness meter allows for on-site control of product surface roughness and is widely used in industries such as sheet materials, automotive parts, aerospace, electronics, solar energy, and printing. It enables fast, non-contact measurement without damaging the workpiece surface.

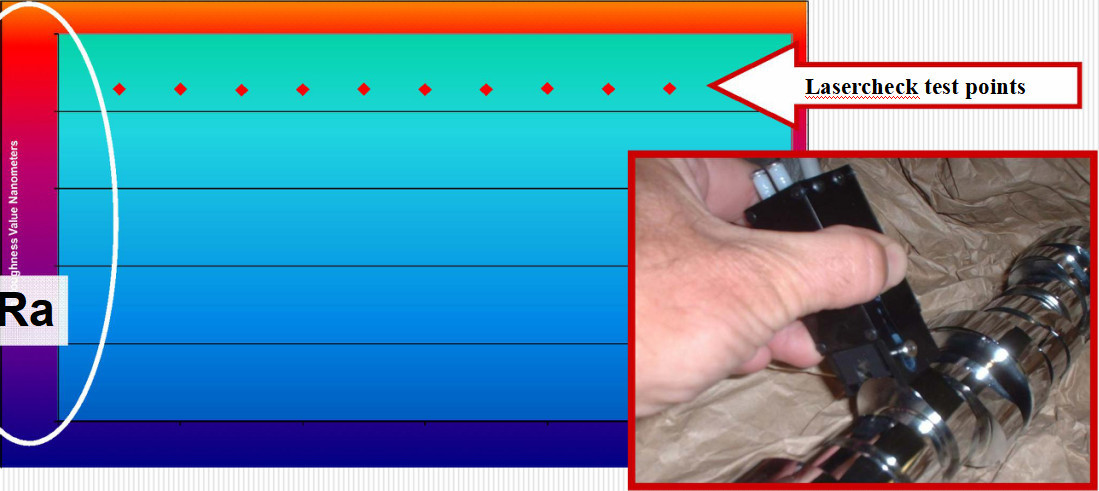

Lasercheck™ Laser non-contact surface roughness online measurement system

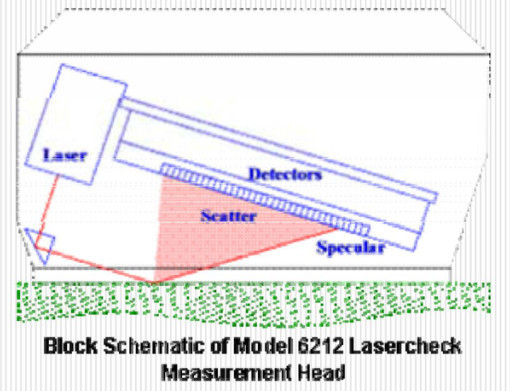

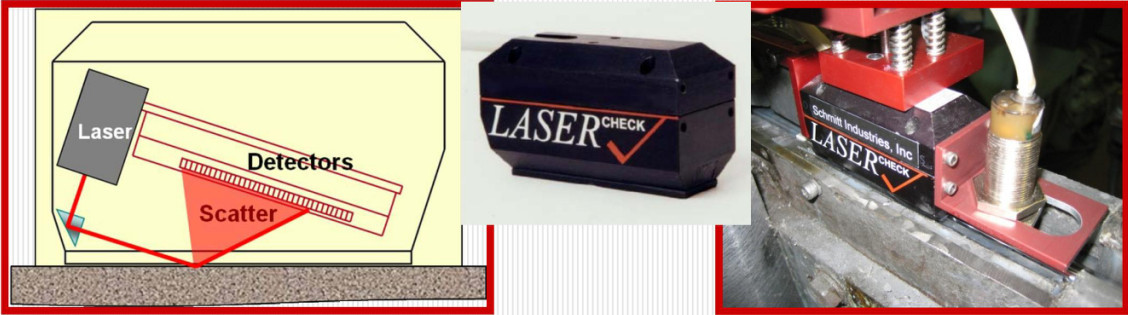

Lasercheck™ Laser roughness measuring instrument Using patented "laser scanning" technology, it performs precise and stable non-contact surface roughness measurement. The measurement range is between 0.01 and 2 microns. All laser measurement heads use a combination of laser illumination light source and multiple sensor detection systems, and are connected to an electronic measurement, amplification and digital surface laser photometric signal processor. This processor can analyze changes in the laser distribution and light intensity reflected from the surface. Then, using unique evaluation software, a detection report of the changes in light intensity on surfaces with different roughness can be generated. The evaluation software and design features of the Lasercheck laser roughness measuring instrument allow it to be installed in the production process for real-time, automatic surface measurement. Using this timely and direct quality feedback, processors can adjust the production process in time to improve the yield, reduce the defect rate, and save production costs.

● Visible laser beam hits the surface of the measured object

● The detector in the probe measures the distribution and brightness of the laser beam reflected from the surface

● Multiple detectors measure the diffuse reflection of the surface

YYL006212 Measurement head

● Multi-purpose, easy to use

● Measurement range: 0.025~2 µm

● Portable and online non-contact measurement

● Robust structure

YYL008826 Measurement head

● The probe is very narrow, < 1 inch

● Can measure the surface of narrow spaces: automotive crankshafts, camshafts

YYL910431 (POM) Display controller

● Usable 6212 or 826 probe

● Input control / Non-conforming product output port enables fully automatic measurement capability

● Based on WindowsCE Friendly user software interface

● Multiple data output options – USB ,RS422 ,Ethernet

Automatic adaptation function:

● Non-conforming products issue alarm signals via relays or open rejection gates

● Analog output proportional to roughness can be fed back to production equipment

Automatic adaptation function:

● Will not be damaged or lose accuracy

● Allows surfaces to move at any speed

● Can compensate for errors caused by vibration

Durable

● No stylus tip wear

● Can withstand harsh workshop environments

● Can save US$1,000 in annual maintenance / repair / calibration costs

Repeatability and reproducibility

● Stable electronic and optoelectronic components

● No moving measuring parts - improves measurement repeatability

● Will not damage the workpiece surface

● Can be installed on the production line for dynamic measurement

● Can only measure and evaluate Ra parameters

Applications

Keywords:

Previous Page

Next Page

Related Products

Product Inquiry