ATOS Core optical scanning system

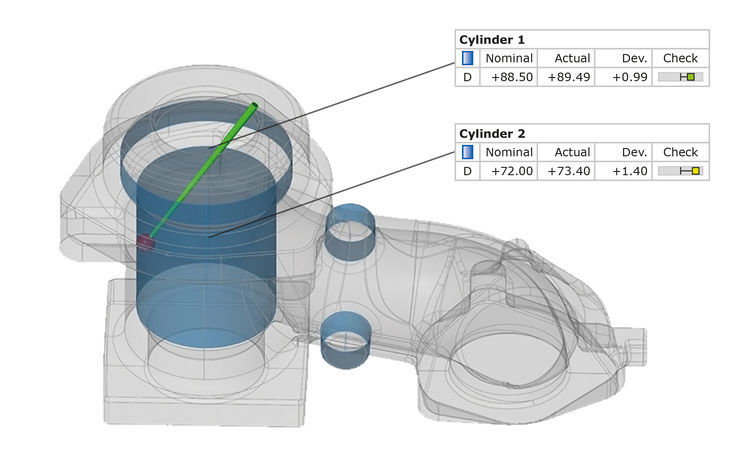

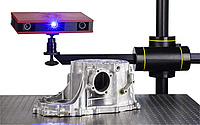

The ATOS Core is specialized for the 3D measurement of small components with dimensions under 500 millimeters. From simple 3D scans to fully automated measuring and inspection processes, its measurement head provides fundamental support for the implementation of various tasks. The ATOS Core is particularly suitable for the 3D measurement of medium and small objects, such as ceramic cores, castings or plastic parts. To measure large objects up to several meters in length using an efficient workflow, the ATOS Core can be quickly and easily combined with GOM's TRITOP optical 3D coordinate measuring device for digital photogrammetry.

Keywords:

3D scanner

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: ATOS Core optical scanning system

The ATOS Core is specialized for the 3D measurement of small components with dimensions under 500 millimeters. From simple 3D scans to fully automated measuring and inspection processes, its measurement head provides fundamental support for the implementation of various tasks. The ATOS Core is particularly suitable for the 3D measurement of medium and small objects, such as ceramic cores, castings or plastic parts. To measure large objects up to several meters in length using an efficient workflow, the ATOS Core can be quickly and easily combined with GOM's TRITOP optical 3D coordinate measuring device for digital photogrammetry.

ATOS Core Innovative Technology

ATOS Core offers seven different probe types for various measurement volumes. These probes can be quickly and reliably exchanged via hot-plugging to meet different resolution and measurement volume requirements.

ATOS Core Features

Compact Scanning Probe

Highly Stable Structure

Blue Light Technology

Triple Scan Principle

Dynamic Real-time Tracking

Optical Probe

ATOS Core Applications

ATOS Core can be used for 3D measurement of small and medium-sized parts such as ceramic cores, castings, and plastic parts. From simple 3D scanning to fully automated measurement and inspection, ATOS Core plays an important role in handling various measurement tasks.

When using 3D printing technology to manufacture parts, it is crucial to ensure precise geometric dimensions. This means companies must effectively address the issues of part shrinkage and warping inherent in additive manufacturing processes. Optical measuring instruments can assist in this, as they can detect all deviations present in the parts.

All detected parameter fluctuations during manufacturing must be accurately recorded. In the case of manufacturing a car engine hood using 3D printing technology, GOM technology ensures precise replication of the original part and effectively identifies and corrects all geometric deviations that occur during manufacturing.

One core device, three product combinations

Essential Line

The Essential Line is primarily designed for simple 3D scanning tasks such as reverse engineering or rapid prototyping. It's the ideal choice for users who want to experience GOM's high quality or are just starting out with 3D scanning. This package includes the ATOS Core measuring head, GOM Scan application software, an image processing computer, and other accessories. The GOM Scan software is intuitive and easy to use. Used with the ATOS Core measuring head (2M or 5M measuring head), it produces high-quality 3D polygon meshes, which can be output as STL files. The manual operating system includes three types of stands: column, tripod, and table. If needed, you can upgrade from the Essential Line to the Professional Line at any time.

Professional Line

The Professional Line excels at providing effective solutions for complex metrology tasks. The plug-and-play (PnP) advantage of the measuring head allows for timely on-site exchange of suitable measuring heads to meet different resolution and measurement volume requirements. In addition to the hardware configuration of the Essential Line, the Professional Line also includes the powerful ATOS Professional application software. This globally renowned measurement and inspection software features many innovative features and functions. Functions include Triple Scan, polygon mesh editing, inspection, report writing, Teaching by Doing, scripting, reverse and selective projection, and Motion Replay, dynamic reference, etc., related to contact probe, tracking, and adapter applications. Additionally, photogrammetry and automated measurement using a turntable are optional.

Kinematics Line

The Kinematics Line is a fully automated metrology solution designed to increase throughput, productivity, and repeatability in industrial quality control processes for small parts. In addition to the hardware configuration of the Professional Line, the Kinematics Line can be used with an industrial robot along with the ATOS ScanBox. The scanning process is supported and managed by the ATOS Professional software. Combined with the powerful Virtual Measuring Room (VMR) software module, this creates a simulation environment, enabling users to create automated programs offline and online on an easy-to-use platform. Additionally, with the optional fully integrated photogrammetry function of ATOS Plus, the Kinematics Line can also perform reference point determination.

Related Products

Product Inquiry