RT multi-angle high-speed scanning detection system

The RT scanning detection system is a high-speed, high-precision, automatic measurement system developed based on extensive experience in dimensional measurement projects and is used for production lines, line sides, or laboratories. It integrates non-contact 3D laser profile sensing technology and MAS (multi-angle, multi-station scanning) patented technology.

Keywords:

3D scanner

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: RT multi-angle high-speed scanning detection system

The RT scanning detection system is a high-speed, high-precision, automatic measurement system developed based on extensive experience in dimensional measurement projects and is used for production lines, line sides, or laboratories. It integrates non-contact 3D laser profile sensing technology and MAS (multi-angle, multi-station scanning) patented technology.

I. Introduction to MAS and RT

MAS (Multi-Angle Sensing) Technology

• MAS technology, or multi-angle (multi-station) sensing technology, incorporates multiple patented/proprietary technologies. It is a non-traditional high-speed, high-precision 3D scanning and detection technology (method) that can replace traditional measurement methods such as CMMs, image measuring systems, profilometers, and height gauges, shortening cycle times CT.

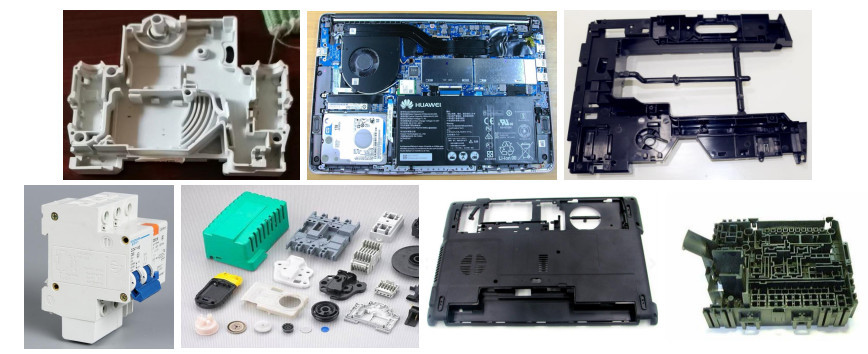

• Main applications: Flat parts such as mobile phones, smartwatches, tablets, keyboards, low-voltage electrical appliances, hard drive bodies, or similar parts requiring high-speed, high-precision 3D scanning and detection with numerous dimensions (online or large-sample inspection).

• Based on laser line scanning or other 3D scanning sensors, 2D measurement can be optionally added.

RT scanning (equipment )

• RT = REBIASTEC®, or deviation reset technology (also known as Real-Time/high-speed), is a high-speed measurement and data application solution for high-quality manufacturing (weakly standardized cloud collaborative manufacturing technology).

• RT scanning is a line laser multi-angle detection module and software (algorithm) developed based on MAS technology. It can be equipped with a multi-axis mechanism to achieve high-speed and high-precision 3D scanning measurement (software is compatible with 2D measurement).

II. Technical Issues and Applications Solved by MAS/RT

Fusion of multiple 3D scan data

• Fusion of scan data from multiple positions and angles of a single sensor.

• Fusion of data from multiple different scanning sensors.

• Fusion of scan data from multiple stations of one or more scanning sensors.

Dynamic error compensation for multi-degree-of-freedom measurement systems

• Single-axis or multi-axis measurement systems

• Multi-axis positioning guide mechanism

III. RT Scanning System—MAS-Based Product

RT High-Speed 3D Scanning and Detection System (Module)

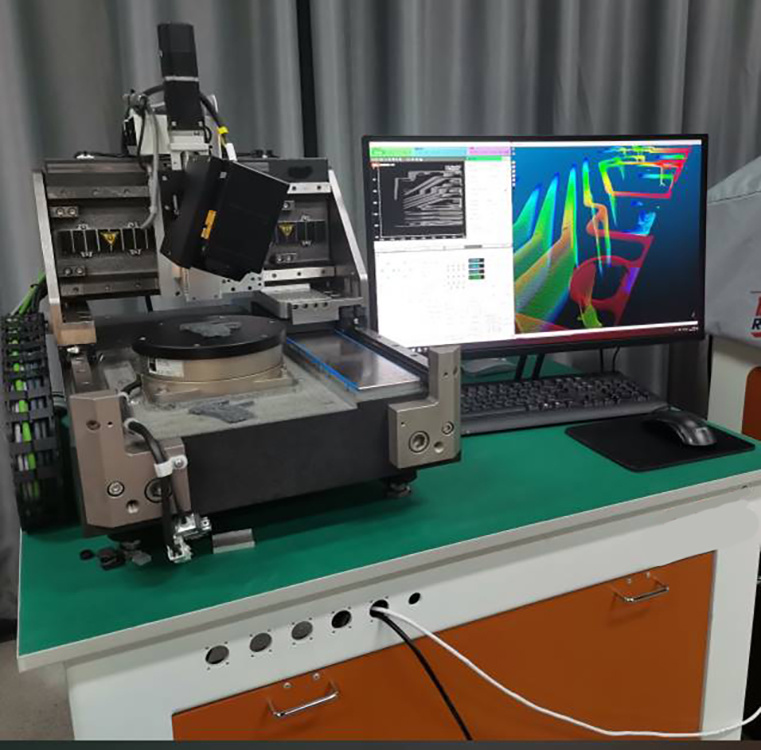

• LDI.RT: A conventional high-speed scanning and detection system developed based on MAS technology.

• X.RT: A non-standard high-speed scanning and detection system based on MAS, customized according to customer project requirements.

• RT, as an independent 3D scanning module, can be embedded into user production line equipment.

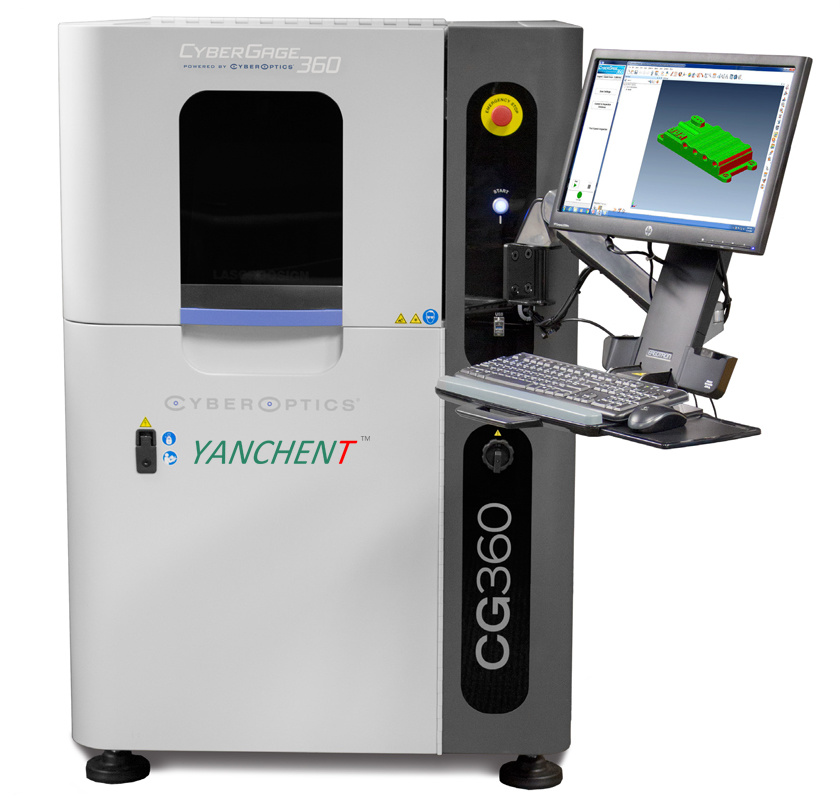

Competitors/Benchmark Products

• CyberOptics' SQ3000 automatic optical coordinate measuring AOI system and CG360 fully automatic 3D scanning and detection system.

• LDI-SurveyorXS bridge-type general-purpose high-precision 3D laser scanning system

IV. Physical Images: LDI.RT and .SurveyorDS

CyberSCANERS—CG360™ One-Click 3D Scanning Point Cloud Detection System

The CG360 is a metrology-grade non-contact geometric dimension inspection equipment specially designed for high-throughput 3D scanning. It can be widely used in production lines or metrology laboratories to achieve high-precision 3D

The speed, accuracy, and ease of operation of detection are insufficient. 3D scanning and detection reports are completed in less than three minutes. High-precision scanning supported by powerful MRS technology—Accuracy up to: 7μm,

0.007mm + L/10000mm—Multiple reflection suppression technology (MRS) reduces measurement deformation to achieve metrology-grade accuracy. Simple operation: One-click completion of scanning and generation of detection reports.

Simple operation.

I. Main Parameters

Measurement range: Sample less than 200mm in diameter x 100mm in height

Accuracy: Spatial accuracy 7µm, repeatability 5µm

Speed: 16 million scan points, single-piece scan and detection time <3 minutes

System configuration: 2 scanning heads (1 each on the upper and lower parts of the worktable)

Load capacity (max): 2kg for glass platform, 5kg for built-in support. Data output format: .STL, .PLY, .OBJ, .ASC

Temperature and humidity requirements: Temperature 20±3℃, humidity 50%±30%. One-click completion of scanning and generation of detection report

II. Standard Configuration

Scanning host, built-in customized PC control system

Polyworks Inspector measurement software

RT high-speed high-precision 3D laser sensor (partial)

III. Technical Advantages of MAS/RT

MAS (patented/proprietary) technology can achieve

• Online fusion of scan data from multiple angles, multiple sensors, and multiple stations (can meet online detection requirements).

• Dynamic error compensation for multi-axis system mechanisms.

Typical Projects (Based on Verifier Test and Evaluation)

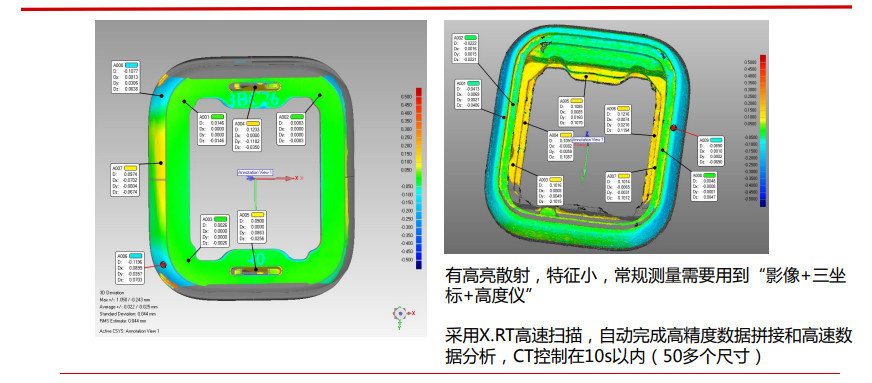

• Online inspection of smartwatches for a certain 3C device, reducing the inspection time per item from more than 10 minutes to 10 seconds.

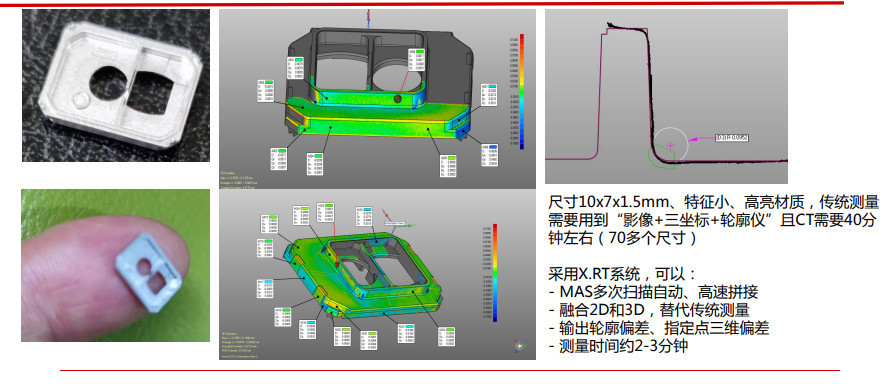

• 3D measurement of camera brackets for a certain mobile phone manufacturer, reducing the inspection time per item from more than 30 minutes to about 2 minutes. Calibration of scanning and positioning guidance for a certain 3C five-axis mechanism manufacturer, reducing system error from 0.10mm to 0.02mm.

• Fast scan detection of multi-feature components for a certain communication equipment company, reducing measurement time from 120 minutes to about 20 minutes.

• High-speed 3D detection of precision injection molded parts for a certain electrical appliance, shortening the measurement time for 170 dimensions of a single sample to within 3 minutes.

• Comprehensive dimensional inspection of power supply products, high-precision robot 3D scanning system MARS

IV. Applicable Departments

Automated 3D scanning and measurement equipment that does not require professional metrologists, can be used for:

• Production (large-scale on-line or in-line measurement in the workshop): Full or sample inspection of products during the production process (largely replacing traditional measurement methods) to ensure stable quality

• Trial production (small-batch off-line measurement): Scanning trial products, comparative analysis, and improvement plans

• Design (off-line laboratory measurement): Scanning, analysis, and reverse modeling of competing products or trial products to improve efficiency

• Quality (real-time data analysis): Failure analysis, supplier quality inspection, etc.

• Others: 3D printed product size control, product development, CAE analysis, etc.

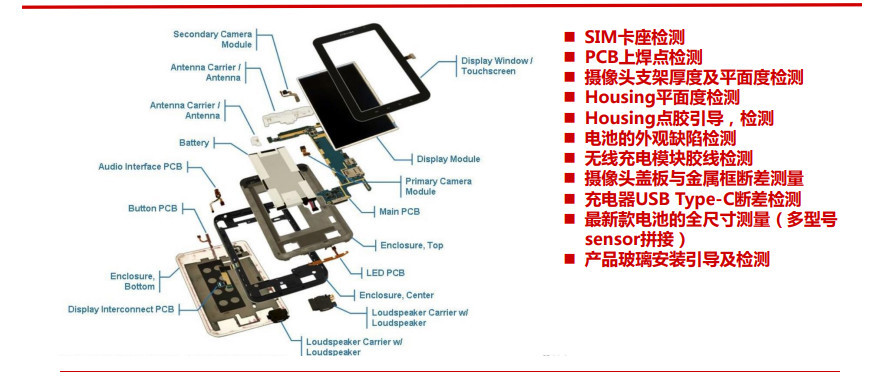

Five, Applicable Products: Precision plastic parts, PCBAs, etc.

Applicable to: Machining, metal 3D printing, precision die castings, etc.

Six, Case One: High-speed dimensional measurement of a mobile phone camera bracket

Case Two: On-line 3D contour inspection of a smart watch body

Examples of RT applications in the 3C industry

Previous Page

Related Products

Product Inquiry