CP Series Step Machine

The CP series step profiler is an ultra-precise contact-type micro-profile measuring instrument, mainly used for measuring micro-morphology parameters such as step height, film thickness, and surface roughness. During measurement, a 2μm radius diamond stylus scans the sample surface while moving on an ultra-precision displacement stage. The vertical displacement of the stylus is converted into an electrical signal matching the feature size and finally into a digital point cloud signal. The data point cloud signal is displayed in the analysis software, and different analysis tools are used to obtain data related to surface quality, such as step height or roughness.

Keywords:

Electronics and Electrical Engineering

Dimension measurement

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: CP Series Step Machine

The CP series step profiler is an ultra-precise contact-type micro-profile measuring instrument, mainly used for measuring micro-morphology parameters such as step height, film thickness, and surface roughness. During measurement, a 2μm radius diamond stylus scans the sample surface while moving on an ultra-precision displacement stage. The vertical displacement of the stylus is converted into an electrical signal matching the feature size and finally into a digital point cloud signal. The data point cloud signal is displayed in the analysis software, and different analysis tools are used to obtain data related to surface quality, such as step height or roughness.

Product Description

The CP series step profiler is a ultra-precision contact-type micro-profile measuring instrument, mainly used for measuring micro-morphology parameters such as step height, film thickness, and surface roughness. During measurement, a 2μm radius diamond tip scans the sample surface while moving the sample on an ultra-precision displacement stage. The vertical displacement of the probe is converted into an electrical signal matching the feature size and finally converted into a digital point cloud signal. The data point cloud signal is presented in the analysis software, and different analysis tools are used to obtain data related to surface quality, such as step height or roughness.

Product appearance image

The CP series step profiler adopts a linear variable differential capacitance sensor (LVDC), which has the ability of ultra-micro force adjustment and sub-angstrom resolution. At the same time, it integrates core technologies such as ultra-low noise signal acquisition, ultra-fine motion control, and calibration algorithms, enabling the instrument to have ultra-high measurement accuracy and repeatability.

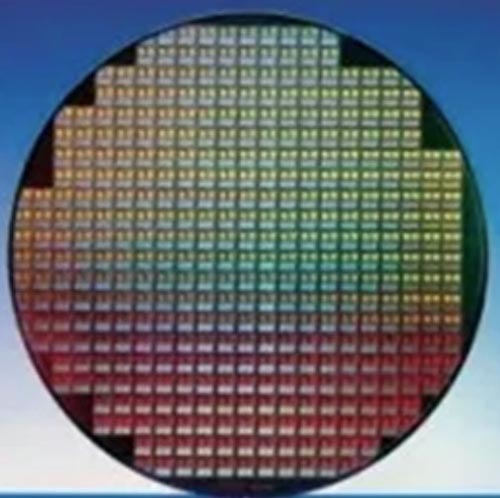

The CP series step profiler has strong adaptability to application scenarios. It has no special requirements for the reflectivity characteristics, material types, and hardness of the sample to be measured. It can be widely used in industrial enterprises and scientific research institutions in various industries such as semiconductors, solar photovoltaics, optical processing, LEDs, MEMS devices, and micro-nano material preparation. The accurate characterization of surface micro-morphology parameters is of great significance to the evaluation of related materials, performance analysis, and process improvement.

Product Functions

1. Parameter Measurement Function

1) Step Height: Able to measure step heights from nanometers to 330μm or even 1000μm. It can accurately measure materials deposited or removed during processes such as etching, sputtering, SIMS, deposition, spin coating, and CMP;

2) Roughness and Waviness: Able to measure the roughness and waviness of the sample. The analysis software calculates the microscopic profile curve scanned to obtain more than 20 parameters related to roughness and waviness, such as Ra, RMS, Rv, Rp, and Rz;

3) Warpage and Shape: Able to measure the 2D shape or warpage of the sample surface. For example, in semiconductor wafer manufacturing, warpage or shape changes caused by interlayer mismatch in multilayer deposition structures, or the height and radius of curvature of structures such as lenses.2. Data Acquisition and Analysis System

1) Customized Measurement Mode: Supports users to set the measurement mode of the scanning path by customizing input coordinate positions or relative displacement amounts;

2) Navigation Map Intelligent Measurement Mode: Supports users to intelligently generate moving commands based on the navigation map, calibration data, and real-time images to achieve the scanning measurement mode.

3) SPC Statistical Analysis: Supports the analysis of multiple index parameters for different types of test pieces. It provides SPC charts for the measurement data of batch samples to show the changing trend of the data.3. Optical Navigation Function

Equipped with a 500W pixel color camera, it can transmit the morphology image of the probe scanning trajectory to the software in real time for display, enabling real-time high-precision positioning measurement.

4. Sample Space Posture Adjustment Function

Equipped with a precision XY stage, a 360° electric rotary platform, and an electric lifting Z-axis, it can adjust the XYZ and angle of the sample's spatial posture, improving measurement accuracy and efficiency.Performance Characteristics

1. Sub-angstrom Displacement Sensor

It has sub-angstrom resolution and combines a single-arch gantry design to reduce environmental noise interference, ensuring that the instrument has good measurement accuracy and repeatability;2. Ultra-micro Force Constant Force Sensor

Adjustable from 1-50mg to adapt to the surfaces of hard or soft samples. Using ultra-low inertia design and micro electromagnetic force control to achieve non-contact damage contact measurement;3. Ultra-flat Scanning Platform

The system is equipped with ultra-high straightness guide rails to eliminate subtle vibrations during movement and truly restore the contour undulation and micro-morphology of the scanned trajectory.

Typical Applications

Semiconductor Applications

Step height of deposited thin films

Step height of resist (soft film material)

Etch rate determination

Chemical mechanical polishing (corrosion, pitting, bending)

Large Substrate Applications

Printed circuit boards (protrusions, step height)

Window coatings

Wafer masks

Wafer chuck coatings

Polishing plates

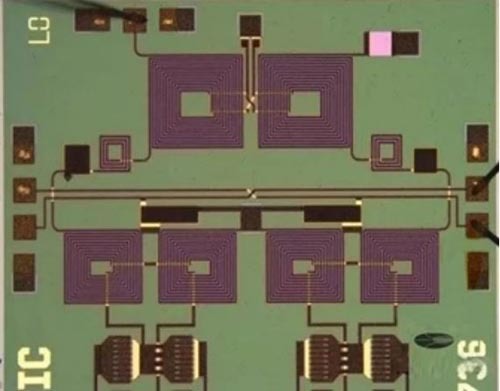

Glass substrate and display applications

AMOLED

Step height measurement in LCD screen research and development

Touch panel film thickness measurement

Solar coating film measurement

Flexible electronic device film applications

Organic photodetectors

Organic films printed on films and glass

Touch screen copper tracesTechnical Parameters

Model CP200 Measurement Technology Probe-type surface profile measurement technology Sample Observation Optical Navigation Camera: 5-megapixel high-resolution color camera, FoV, 2200*1700μm Probe Sensor Ultra-low inertia, LVDC sensor Measurement Force 1-50mg adjustable Probe Selection Probe radius of curvature 2μm, angle 60° Platform Movement Range X/Y Electric X/Y (150mm*150mm) (Manually Leveled) Sample R-θ Stage Electric, 360° continuous rotation Single Scan Length 55mm Maximum Sample Thickness 50mm Maximum Wafer Size on Stage 150mm (6 inch), 200mm (8 inch) Step Height Repeatability 5 Å, when the range is 330μm / 10 Å, when the range is 1mm

(Measuring 1μm step height, 1δ)Sensor Range*1 330μm or 1mm Vertical Resolution Resolution <0.01 Å (when the range is 13μm) Scanning Speed 2μm/s-10mm/s Dimensions (L×W×H) mm 640*626*534 Weight 40kg Instrument Power Supply 100-240 VAC, 50/60 Hz, 200W Operating Environment Relative Humidity: Humidity (no condensation) 30-40% RH

Temperature: 16-25℃ (Temperature change less than 2℃ per hour)

Ground Vibration: 6.35μm/s (1-100Hz)

Audio Noise: ≤80dB

Air Laminar Flow: ≤0.508 m/s (downward flow)

Previous Page

Related Products

Product Inquiry