JWR-30plus pyrolysis desorption instrument

The JWR-30plus pyrolysis desorption instrument is a rapid screening solution for multiple phthalates in response to new regulations such as RoHS2.0, California 65, REACH, and EN71.

Keywords:

Physical property testing

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: JWR-30plus pyrolysis desorption instrument

The JWR-30plus pyrolysis desorption instrument is a rapid screening solution for multiple phthalates in response to new regulations such as RoHS2.0, California 65, REACH, and EN71.

JWR-30plus Thermal Desorption Instrument

Complies with RoHS 2.0, California Proposition 65, REACH, EN71, and other regulations

Added multiple rapid screening solutions for phthalates

2015 Year 6 Month 4 Day EU Official Journal ( OJ ) published RoHS 2.0 Amendment Directive (EU) 2015/863 based on the original RoHS 6 substances (lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers), added 4 phthalates RoHS 2.0 to the list of restricted substances. Thus far, RoHS 2.0 the number of controlled substances has reached 10 items.

According to RoHS 2.0 the testing standards, production enterprises need to purchase related equipment for rapid screening of raw materials, material self-inspection, internal quality control, customer factory audits, etc. (Regularly configured instruments: GCMS+EDXRF spectrometer). However, the purchase of this equipment often costs millions, which is a huge pressure for many enterprises. Enterprises cannot avoid raw material screening; otherwise, huge hidden dangers will be buried in product production, and enterprises cannot control whether their products meet the standards. Based on the importance of internal screening and the huge investment required for equipment purchase, a new solution is specially developed for RoHS 2.0 the 4 types of phthalates rapid screening needs: JWR-30plus thermal desorption phthalate rapid screening solution.

The JWR-30plus system is an upgraded and more advanced and efficient thermal desorption instrument based on the TP20-GC. In addition to meeting the phthalate detection requirements of RoHS 2.0, it can also be expanded to TOTM (trioctyl trimellitate), DMF (dimethylformamide), benzene series (benzene, toluene, xylene), 17 VOCs in inks, organic solvent residues, polymer materials, and volatile organic compounds in materials, etc. Powerful functions!

Advantages of the JWR-30plus solution:

1. Short sample preparation time: The sample preparation time of 20 minutes/sample fully meets the rapid screening needs of enterprise users;

2. No waste gas or liquid is produced: This method requires no reagents, no pretreatment, and produces no waste gas or liquid;

3. Low procurement cost: The procurement cost of PY+GCMS is 1.5 million, and the procurement cost of JWR-30plus is less than 400,000;

4. Low operating cost: No pretreatment, no reagents and consumables are required, and the annual operating cost is less than 3,000 yuan;

5. Direct injection, simple operation: Direct solid or liquid injection, five-step operation to obtain results, production line workers can operate;

6. Built-in standard curve: More intuitive judgment of whether the material exceeds the phthalate standard (unique technology);

7. Applicable to 100% polymer materials: Chemical methods are only suitable for 70% of materials, while JWR-30plus is suitable for 100% of materials;

8. No professional laboratory environment is required: It only needs a general operating space with air conditioning and power supply for installation and use;

9. Programmable temperature rise: 5 degrees/degree programmable temperature rise, effectively coping with more complex substances;

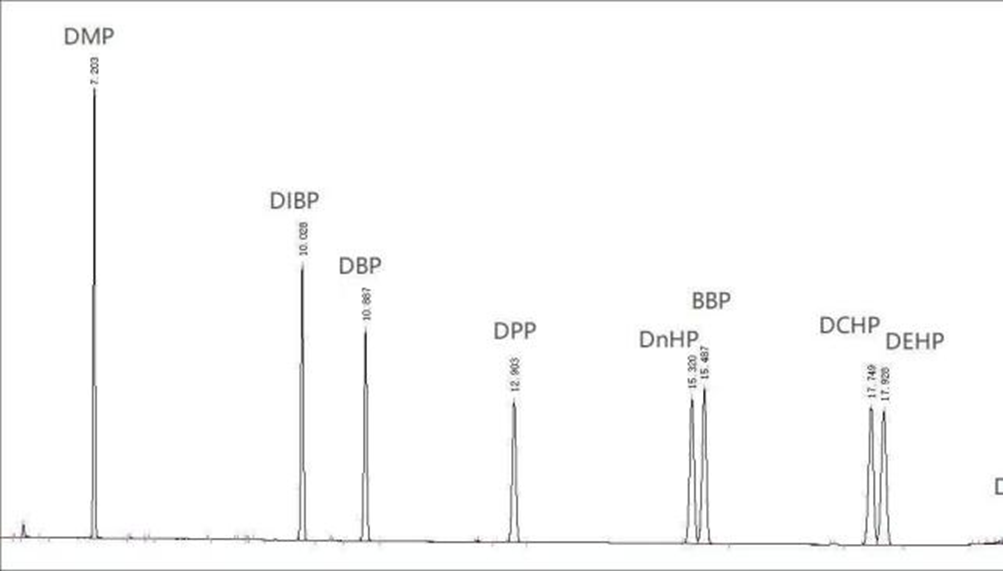

8 Rapid detection spectrum of phthalates

Instrument accuracy and reliability test:

Experimental section: Instruments and consumables

1. Gas chromatograph with EPC control;

2. JWR-30plus thermal desorption instrument (pyrolysis desorption temperature 200℃-650℃);

3. Chromatography workstation (with reverse control function);

4. Special capillary column for phthalates;

5. Nitrogen, hydrogen, and air sources;

6. 1/10000 analytical balance; Pretreatment process:

This method requires no pretreatment. The consumables are 2.5cm long quartz tubes, quartz wool, and pretreatment columns. Place the solid sample in the middle of the quartz tube and fix both ends with quartz wool. Then, place the prepared sample tube into the heating chamber.

Analysis conditions:

Thermal pyrolysis temperature program 200℃-450℃

Micro-pyrolysis time 2 min Injection method: Split injection Liquid injection volume: 1 ul

Solid injection volume: 5mg or less Inlet temperature: 250 ℃

FID detector temperature: 300 ℃

Programmable temperature rise 50 ℃ (hold for 1 min), increase to 450 ℃ at 20 ℃ per minute (hold for 4 min)

Component name and retention time

Name

Abbreviation

Retention time

Time window

Remarks

Diisobutyl phthalate

DIBP

8.524

0.05

Dibutyl phthalate

DBP

9.041

0.05

Benzyl butyl phthalate

BBP

10.941

0.05

Bis(2-ethylhexyl) phthalate

DEHP

11.949

0.05

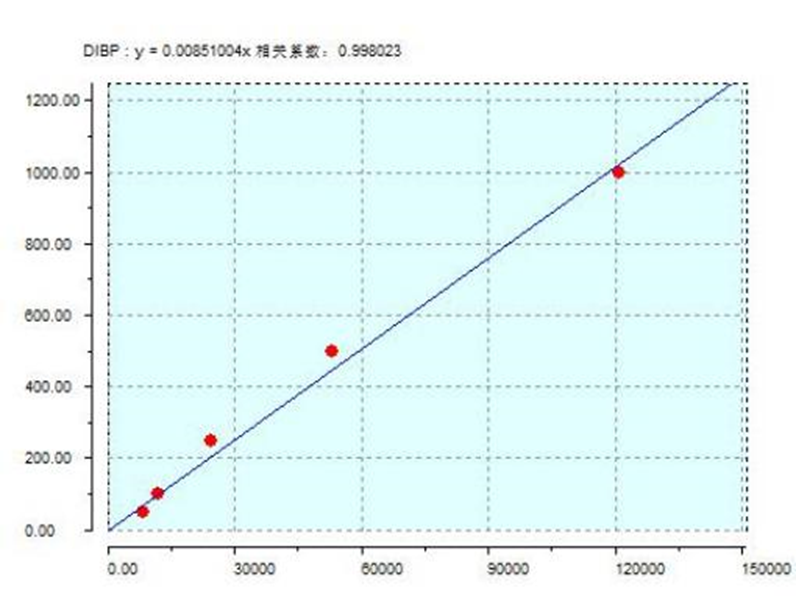

Standard curve and linear range (limit of detection)

The concentration is 50 ppm 、100 ppm 、250 ppm 、500 ppm and 1000 ppm of DIBP standard solution, with concentration as the abscissa and quantitative components peak area as the ordinate, a standard curve is drawn. The standard curve and linear correlation coefficient are as follows shown.

The following table shows a comparison chart of peak height and peak area for 5 different concentration standards:

Concentration (ppm)

Peak height (pA)

Peak area (A)

50

2038.7

8472.5

100

2829.6

12607.7

250

5720.6

24674.0

500

12090.8

53037.4

1000

24747.2

120759.3

Repeatability (precision experiment): Repeatability determination was carried out at the lowest detection limit concentration, and the results are shown below.

RSD%

DIBP

Peak height

Peak area

1

944.8

3484.2

2

1007.3

3638.8

3

903.2

3167.9

4

1205.6

4227.6

RSD%=5.24

Previous Page

Related Products

Product Inquiry