HYHVS-1000ZT2.1 automatic micro-Vickers hardness tester

The HYHVS-1000ZT2.1 automatic microhardness tester features a 5.6-inch LCD touchscreen main unit, an automatic turret digital micro-Vickers hardness tester, and a micro/Vickers hardness image automatic measurement system. It uses a computer to control the micro-Vickers hardness tester and automatic stage, displaying the hardness indentation image on the computer screen. This hardness testing instrument integrates various professional technologies, including electrical control, optical imaging, mechanical displacement, image analysis, and computer processing.

Keywords:

Hardness tester and consumables

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: HYHVS-1000ZT2.1 automatic micro-Vickers hardness tester

The HYHVS-1000ZT2.1 automatic microhardness tester features a 5.6-inch LCD touchscreen main unit, an automatic turret digital micro-Vickers hardness tester, and a micro/Vickers hardness image automatic measurement system. It uses a computer to control the micro-Vickers hardness tester and automatic stage, displaying the hardness indentation image on the computer screen. This hardness testing instrument integrates various professional technologies, including electrical control, optical imaging, mechanical displacement, image analysis, and computer processing.

HYHVS-1000ZT2.1 Automatic Micro-Vickers Hardness Tester

Product Overview:

The HYHVS-1000ZT2.1 automatic micro-hardness tester features a 5.6-inch LCD touchscreen, an automatic turret digital micro-Vickers hardness tester, and a micro/Vickers hardness image automatic measurement system. It controls the micro-Vickers hardness tester and automatic stage via computer, displaying the hardness indentation image on the computer screen. This hardness testing instrument integrates multiple professional technologies, including electrical control, optical imaging, mechanical displacement, image analysis, and computer processing. It uses a precise mechanical design, an ARM high-speed processor for electrical control of the testing process, and a high-definition optical measurement system and photoelectric sensing for optical components, combining mechanics, optics, and electronics to improve the measurement accuracy of micro-Vickers or Knoop hardness.

This hardness tester is suitable for measuring thin specimens, parts with surface渗镀处理 (Note: This term requires further clarification for accurate translation), and brittle materials such as agate, glass, and ceramics, making it an ideal hardness testing instrument for research and testing in colleges and universities, research institutions, factories, and quality inspection departments.

Functions and Features:

The HYHV300T2.1 micro-Vickers hardness image automatic measurement system can directly control the hardness tester host and automatic coordinate stage, allowing real-time image observation and hardness value measurement. It supports both manual and automatic measurement, providing fast and accurate measurements. It can automatically move and read the sample along a preset trajectory, realizing intelligent functions such as automatic turret, automatic loading, automatic displacement, and automatic reading, meeting the needs of high-end users.

- The system uses a 3-megapixel digital camera to capture images, effectively improving measurement accuracy;

- The automatic coordinate stage offers multiple control methods: computer control, manual operation, and joystick operation;

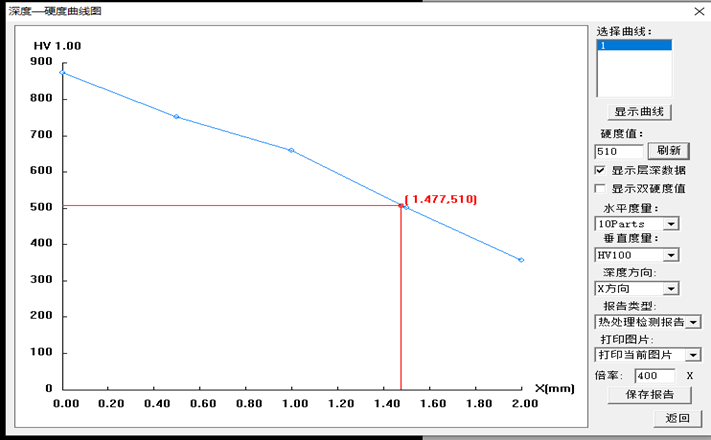

- The system features a one-button measurement function for effective hardened layer depth. The computer controls automatic hardness testing, automatically generates a hardness curve, and automatically calculates the effective hardened layer depth. It can also print the effective hardened layer depth curve and report;

- The system has error correction and calibration functions to correct system errors in the hardness tester;

- It can display the position of the hardness indentation in real time, facilitating the selection of Vickers hardness measurement for different microstructures;

- A system scale can be superimposed on the indentation image;

- The system has database query and management functions.

- Ferrous metals, non-ferrous metals, IC Thin slices, surface coatings, laminated metals;

- Glass, ceramics, agate, gemstones, etc.;

- Measurement of the depth and gradient of carburized layers, nitrided layers, and quenched hardened layers;

- Micro-Vickers hardness measurement of small parts such as thin plates and thin slices.

Main Features of the Host:

- Automatic turret; frictionless spindle, high test force accuracy;

- High-precision optical measurement system, precision coordinate stage;

- Using ARM high-speed processor, 5.6 inch LCD touchscreen;

- English and Chinese interface switching; Various hardness value conversions;

- Dynamic display of the indenter during loading and unloading, real-time observation of the test status;

- The screen displays test force, indentation length, holding time, number of measurements, etc.;

- Automated testing process, simple operation, no human operational errors;

- Automatic correction of hardness values on uneven surfaces;

- Data storage function in the database, test data is stored synchronously and can be exported;

- Equipped with USB and RS232 interfaces, facilitating data processing for users;

- Equipped with a mini-printer for direct printing of test results;

- Knoop indenter can be optionally equipped for Knoop hardness testing;

- Accuracy meets GB/T4340.2 ISO 6507-2 and US ASTM E384 。

Main Technical Parameters:

- Measurement Range: 1-3065HV

- Test Force: 0.09807、0.2452、0.4904、0.9807、1.961、2.942、4.904、9.807 ( N ) 10、 25、 50、 100、 200、 300、 500、 1000 ( gf )

- Hardness Scale: HV0.01、HV0.025、HV0.05、HV0.1、HV0.2、HV0.3、HV0.5、HV1

- Measurement System Magnification: 400 X 、100 X

- Resolution: 0.0625μm , 0.25μm

- Maximum Allowable Specimen Height: 75mm

- Distance from Indenter Center to Machine Wall: 110mm

- Power Supply: AC220V,50/60HZ

- Dimensions: 470 x 320 x 500 ( mm )

- Weight: Approximately 40kg

System Configuration List (including HYHV300T2.1/T3.1 automatic measurement system configuration):

- Automatic Coordinate Stage: 1 pcs

- Platform control box: 1 unit

- Measurement software and dongle: 1 set

- Digital camera and dedicated interface: 1 set

- Dedicated data cable: 1 set

- Brand computer: 1 unit

- Fine axis test stand: 1 pcs

- Thin plate test stand: 1 pcs

- Clamp: 1 pcs

- Large V Standard block: 1 pcs

- Small V Standard block: 1 pcs

- Diamond pyramid indenter: 1 pcs

- Standard microhardness block: 2 block

- Miniature printer: 1 pcs

HYHV300T2.1 Microscopic / Vickers Hardness Image Automatic Measurement System Function Introduction

1 Main functions: (There are slight differences in different versions of the software)

- System linkage: The system uses RS232 interface to achieve linkage between the system and the hardness tester, and the software controls the hardness tester in real time, adjusts the brightness, controls the turret, switches lenses, and loads variable loads and reads directly;

- Pressure linkage: After the hardness tester pressure is converted, the system senses the pressure change and adjusts it in time;

- Turret linkage: The software controls the hardness tester to switch between the objective lens - and the indenter;

- Loading linkage: The software controls the hardness tester to load, without manual control of the hardness tester;

- Measurement linkage: The software controls the hardness tester turret, loads and directly measures the hardness value;

- Platform linkage: Professional automatic platform and control, completely controlled by the system;

- Platform dragging: On the active image, drag the mouse to control the displacement of the platform in various directions;

- Direction setting: Set the corresponding platform displacement direction according to the depth direction to ensure the best measurement results;

- Path planning: The automatic coordinate test stand automatically moves the sample to the specified position according to the set trajectory; Multiple schemes support indentation testing path planning, edge normal can be set, Z character, sawtooth, arc, straight line and other test paths;

- Path adjustment: Any adjustments such as adding, deleting, modifying, and moving can be made at the path points;

- Measurement Range: Supports from 10 grams to 50 kilograms of all force values;

- Image acquisition: Displays the hardness image in real time, can store and print images, and the magnification of the output image can be set;

- Automatic measurement: Automatically finds the four vertices of the indentation and directly reads the hardness value, which is fast and accurate;

- Diagonal measurement: Measure by four side lines tangent to the four vertices of the indentation to read the hardness value;

- Four-point measurement: Click the four vertices of the indentation with the mouse to read the hardness value, and the enlarged image is displayed in real time;

- Automatic scanning: Can automatically scan the sample edge and contour;

- Hardness conversion: According to national standards, automatically perform Brinell - Rockwell - Vickers - Knoop and other hardness value conversions, displayed in real time;

- Depth curve: Draw the hardness - depth curve according to the measured data, and the double hardness curve can be output ( HV and HRC/HRA etc.).

- Graphic report: Automatically records measurement data and automatically generates hardness - depth curve, saves or prints hardness - depth curve, indentation image and all indentation measurement values, all reports are in WORD document format;

- Image printing: Users can set the export mode of indentation images, which are divided into all images, current images, or no image output;

- Result statistics: The measurement results of multiple indentations are displayed in EXCEL Data format export, and automatic statistics of the number of measurements, maximum hardness, minimum value, average value, standard deviation, etc.

2 Main features:

- Wide applicability: Compatible with the full series of Vickers and microhardness testers from Huayin.

- Easy installation: USB2.0 Connects to the computer; no card insertion required during installation.

- Stable performance: Automatic reading is possible as long as the hardness tester image is clear and uniform, even if the indentation has minor scratches or rust.

- Powerful functions: Manual reading, automatic reading, hardness conversion, depth hardness curve, indentation image, and image/text report functions.

- Easy to use: Calibration is performed using hardness blocks, Convenient and quick operation for customers; users can become proficient after a brief training session.

- Automatic reading: Unique automatic reading algorithm for automatic reading of various indentations; high speed and accuracy.

- Good repeatability: High repeatability of automatic reading, meeting professional user requirements.

3、X-Y Automatic coordinate stage parameters :

- The electric stage uses a high-quality stepper motor, with high precision and reliability.

- Operation methods: manual, computer control, or joystick operation.

- Table size: 120 x 130 ( mm )

- X Axis stroke: 50 mm

- X Axis stroke: 50 mm

- Minimum step size: ≤ 2.5 μm

- Repeatability: ≤ 2 μm

- Moving speed: five-speed adjustable

- Power Source: AC 220V ,50/60Hz

- Communication interface: RS232 Serial port

- Weight Approximately 4Kg

4 Main configuration (included in the system configuration list): :

- Automatic Coordinate Stage: 1 pcs

- Platform control box: 1 unit

- Measurement software and dongle: 1 set

- Digital camera and dedicated interface: 1 set

- Dedicated data cable: 1 set

- Computer: 1 unit

Related Products

Product Inquiry