LTS-532V Optical Characteristics Automatic Testing System

The LTS-532V optical characteristic automatic testing system is mainly used for automatically testing the brightness, chromaticity, color temperature, uniformity, contrast, color purity, viewing angle, spectrum, and response time of LCD/OLED, and outputs the test results to an EXCEL report. It can be used with TOPCON spectroradiometer and response time tester, and can be connected to a signal source to achieve automatic measurement. The software interface is user-friendly and easy to operate. The system features high accuracy, high speed, high reliability, and low failure rate.

Keywords:

Photoelectric detection equipment

Optical detection equipment

Electronics and Electrical Engineering

Product Attachments:

Retail Price

Market Price

Weight

Category:

Remaining Stock

隐藏域元素占位

- Product Description

-

- Commodity name: LTS-532V Optical Characteristics Automatic Testing System

The LTS-532V optical characteristic automatic testing system is mainly used for automatically testing the brightness, chromaticity, color temperature, uniformity, contrast, color purity, viewing angle, spectrum, and response time of LCD/OLED, and outputs the test results to an EXCEL report. It can be used with TOPCON spectroradiometer and response time tester, and can be connected to a signal source to achieve automatic measurement. The software interface is user-friendly and easy to operate. The system features high accuracy, high speed, high reliability, and low failure rate.

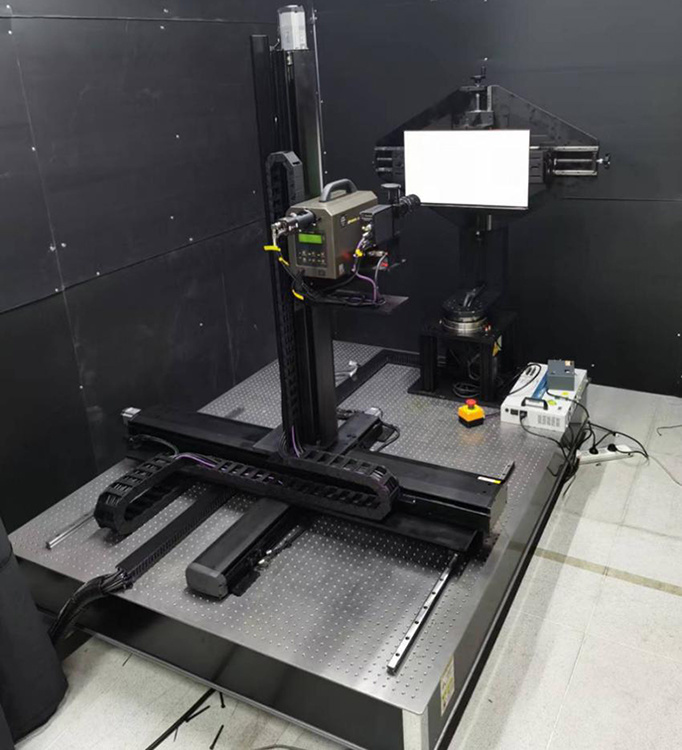

LTS-532V Automatic Optical Characteristic Testing System

1. Equipment Introduction :

Mainly used for automatic testing of LCD/OLED brightness, chromaticity, color temperature, uniformity, contrast, color purity, viewing angle, spectrum, response time, etc., and outputs the test results to an EXCEL report.

It can be used with TOPCON spectroscope radiometer and response time tester, and can be connected to a signal source to achieve automatic measurement.

The software interface is user-friendly and easy to operate. The system has high precision, fast speed, strong reliability, and low failure rate.

2. Product Specifications

Model

LTS-532H

Measurement Method

Product placed vertically, instrument horizontal testing; instrument performs XYZ movement, product performs rotational movement.

Measurement Size Range

800X600mm, maximum thickness 150mm

Measurement Distance

600~800mm

External Dimensions

2500mm (length) × 1500mm (width) x 2300mm (height)

Black baked paint surface

XYZ Effective Stroke

X-axis 800mm Y-axis 600mm Z-axis stroke 800mm Positioning accuracy ±0.02mm,

XYZ Guide Rail Specifications

Japanese THK screw, pitch: 10mm

Two-dimensional Rotation Mechanism

Φ-axis rotation angle ±90°, rotation accuracy ±0.05°

θ-axis rotation angle 0-360°, rotation accuracy ±0.05°

3. Performance Characteristics:

◆360-degree full viewing angle test (AVT) through high-precision brightness, chromaticity, and contrast tests.

◆The company's self-developed test point tracking system (PTS) can ensure accurate positioning regardless of the viewing angle of the tested point.

◆Convenient software operation, after clamping the product, initial positioning can be performed through the video image window. The product center does not need to coincide with the rotation center.

◆Through software settings, uniformity 5-point, 9-point, 13-point, and 25-point tests and viewing angle tests can be completed simultaneously. The entire setting is simple and convenient, and the testing process does not require personnel to monitor the entire process.

◆The software can provide various testing requirements: plane testing, viewing angle testing, connected to the signal generator, automatically providing various signal PANTTEN. The software is open-source and can be programmed according to the customer's own testing requirements.

◆Imported screw rods, guide rails, motors, and drives are used to ensure the reliability of the test.

◆The test program can be saved and quickly loaded during the next test.

◆Reports can be customized according to customer requirements.4. Software Introduction

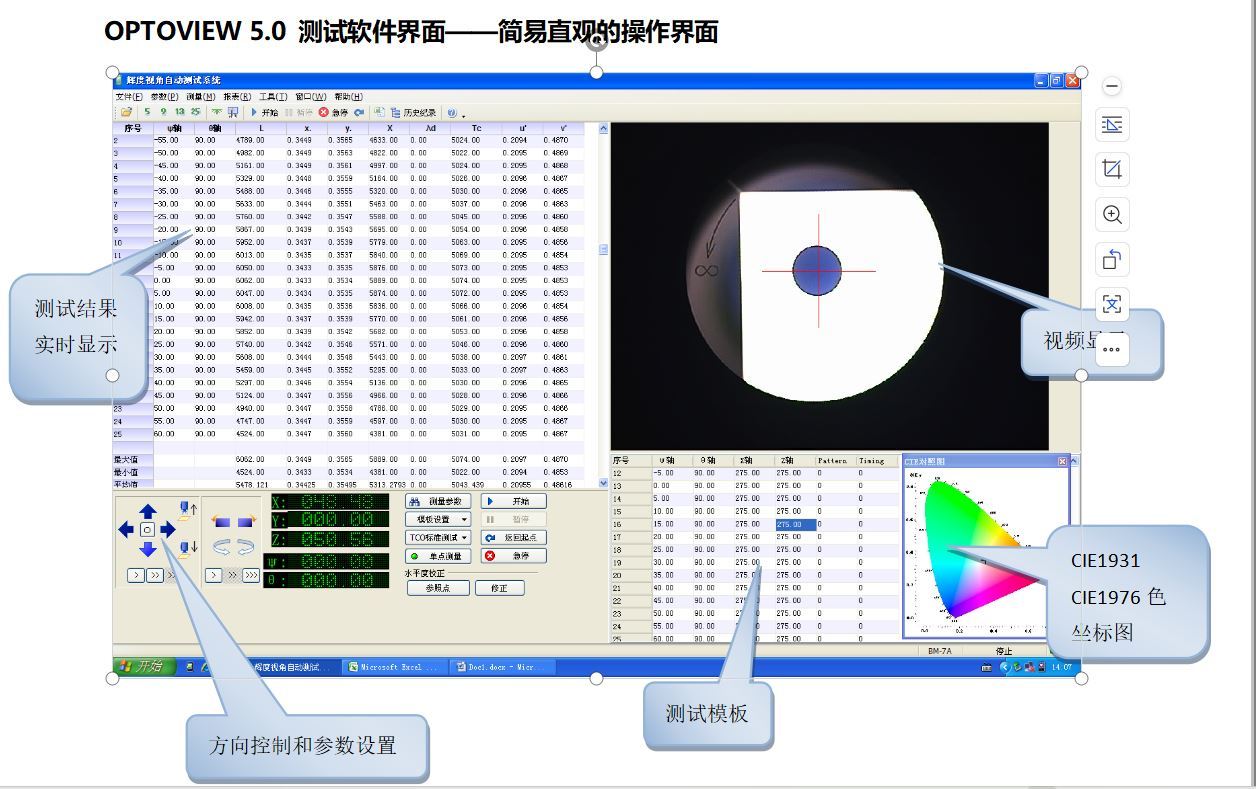

OPTOVIEW 5.0 test software interface - simple and intuitive operating interface

5. Instrument Selection

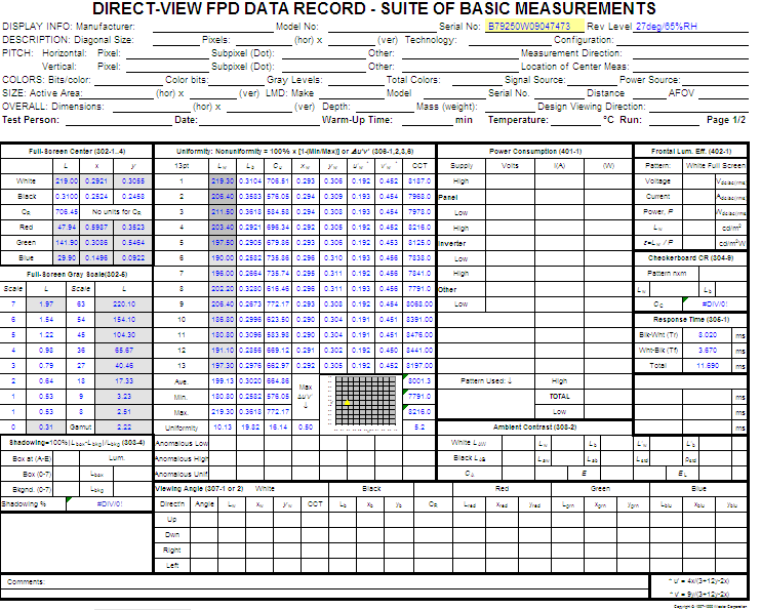

6. Test Report

Previous Page

Next Page

Related Products

Product Inquiry